Demagnetization

Manufacture of many devices and parts of equipment made of steel or other ferromagnetic metals causes magnetizing of these products. To provide the highest quality of products it is needed to decrease their magnetization and thereby retain original characteristics of metal. Then we mean demagnetization or degaussing of magnetic materials.

The origin of magnetism

The magnetizing is carried out during performance of NDT inspection, handling with the magnetic crane, when machining of semimanufactured products, or when milling, cutting, bending, drilling, welding or other mechanical processing. The origin of the magnetic field can be in any environment. But it affects only ferromagnetic materials including iron, nickel and cobalt, or alloys of some elements.

How intensive magnetic field does the Earth generate?

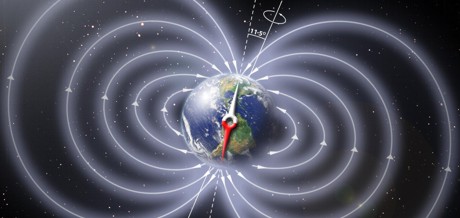

Magnetic field or geomagnetism or the Earth's magnetosphere is an area many thousands, up to one hundred thousand kilometers, around the Earth within which magnetic force operates. This power is generated by friction of the liquid Earth's core with the solid inner core. Magnetic force creates protection for the biosphere (life on the Earth's surface). The value of the magnetic field on the Earth’s surface lies between 25 and 65 microtesla (0.25 to 0.65 Gauss).

Disadvantages of magnetism, residual magnetism

Disadvantages of magnetism, residual magnetism

There are a lot of disadvantages which are result of the product’s magnetizing. These disadvantages include:

- sticking of products in the form,

- rough surface after galvanization,

- difficulties with electric welding,

- faster wearing of bearings,

- metal parts or dust which stick to the products or tools,

- incorrect flaw detection with the help of devices and magnetic probes.

All these disadvantages cause the company considerable financial and time costs. Thus, to prevent the above-mentioned disadvantages it is needed to perform demagnetization. Demagnetization never changes structure of the material and can be repeated.

Measuring of magnetism

Magnetic field intensity gauges are used for measuring of the magnetic field.

Other commonly used names for such gauges are: magnetometer, magmeter, Gaussmeter, Teslameter.

Measurement of residual magnetic field of the product is performed with the help of DC magnetic field intensity gauges.

To measure magnetism formed by alternating AC field one should use AC magnetic field intensity gauges (e.g. when measuring magnetic field between the poles of AC hand yoke).

Company PTS Josef Solnař produces magnetomneters of MH series (click on picture), perform calibration and maintenance of any gauges for measuring of magnetic field intensity.

The measurement is performed by applying of so-called Hall probe and, in such units as kA/m, Gauss or Tesla depending on the model.

How to choose suitable gauge from the offer?

Decreasing of magnetism (demagnetization)

In case your products, tools, consumables etc. are magnetized, it is needed to proceed to demagnetization. This could be realized by demagnetizing equipment.

Demagnetizing coils are designed to reduce residual magnetism by flow of alternating magnetic field of demagnetizing coil through the material.

Demagnetizing tunnels with frequency converter are used for demagnetization of materials in case when other standard methods fail. Our company developed system of individual orders to satisfy even the most demanding requirements of customers and successfully export its equipment to other countries such as Canada, Turkey, Switzerland, Ukraine.

Line Demagnetizers are designed to demagnetize products (pipes, rods) when performing their mass non-destructive testing in NDT or production lines. Their design can include DC and AC coil, or AC coil only.

Special demagnetizing devices are equipment manufactured according to specific customers’ requirements. They are designed according to specific narrowly defined requirements to meet the requirements of magnetic field intensity and external dimensions.

Portable demagnetizers include table demagnetizing device. It is a practical universal device which is used to demagnetize various small products and parts, for example, gauges, tools, etc. made of ferromagnetic materials. The device is not intended for continuous operation.

Ask yourself what you are interested in, call or use the contact form at the bottom of the page.

Reference