Probes for hardness testers

Dynamic and UCI probes for protable hardness testers.

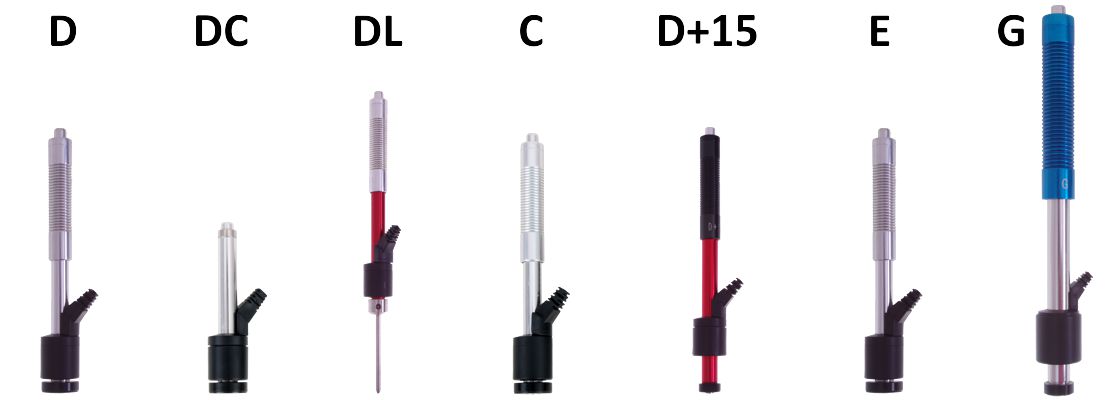

Types of dynamic probes (Leeb probe)

There are 6 basic probes marked as (D, DC, D+15, DL, C, G and E) suitable for different applications. Each special probe is compatible with universal D probe.

Selection of suitable probe

Probe D: universal use, suitable for most applications

Probe DC: with the smallest size is intended for hardly accessible measuring

Probe DL: for use in holes, cavities and grooves

Probe C: for measuring of hardened surfaces

Probe D+15: for use in holes, cavities and grooves

Probe G: intended for large parts with rougher surface

Probe E: with diamond tip ensures longer operation life

The probes are universal and can be used with a majority of portable hardness testers with external probe. We recommend to use them with HardCheck hardness tester.

| PROBE | D | DC | D+15 | DL | C | G | E | |

| impact energy [Nmm] | 11 | 11 | 11 | 11 | 3 | 90 | 11 | |

|---|---|---|---|---|---|---|---|---|

| length [mm] | 150 | 85 | 165 | 202 | 140 | 250 | 155 | |

| diameter [mm] | 20 | 20 | 20 | 20 | 20 | 30 | 20 | |

| weight [g] | 75 | 50 | 80 | 100 | 75 | 250 | 100 | |

| max. hardness of etalon | 940HV | 940HV | 940HV | 950HV | 1000HV | 650HB | 1200HV | |

| PREPARATION OF ETALON | ||||||||

| Roughness RA [µm] | 2 | 2 | 2 | 2 | 0.4 | 7 | 2 | |

| min. thickness [mm] | 3 | 3 | 3 | 3 | 1 | 10 | 3 | |

| min thickness of coating [mm] | 0.8 | 0.8 | 0.8 | 0.8 | 0.2 | ---- | 0.8 | |

| min.weight [kg] | 5 | 5 | 5 | 5 | 0,5 | 15 | 5 | |

| min. weight with stand [kg] | 2 | 2 | 2 | 2 | 0,5 | 5 | 2 | |

| min. weight when connected with stand [kg] | 0.1 | 0.1 | 0.1 | 0.1 | 0.02 | 0.5 | 0.1 | |

| IDENTIFICATION OF IMPACT | ||||||||

| for 300HV, diameter [mm]/depth [µm] | 0.52/24 | 0.54/24 | 0.54/24 | 0.54/24 | 0.38/12 | 1.03/53 | 0.54/24 | |

| for 800HV, diameter [mm]/depth [µm] | 0.35/10 | 0.35/10 | 0.35/10 | 0.35/10 | 0.30/7 | .../... | 0.35/10 | |

| APPLICATION | ||||||||

| steel | HV | 80-940 | 80-937 | 80-950 | 80-996 | ..... | 84-1027 | |

| HB | 80-647 | 80-638 | 81-646 | 80-683 | 90-646 | 84-656 | ||

| HRB | 38.4-99.5 | ..... | 37.0-99.9 | ..... | 47.7-99.9 | ..... | ||

| HRC | 20.0-68.0 | 19.3-67.9 | 20.6-68.2 | 20.0-69.5 | ..... | 21.9-70.5 | ||

| HSD | 32.5-99.9 | 33.3-99.3 | 30.6-69.8 | 31.9-102.3 | ..... | 35.5-102.8 | ||

| tool steel | HV | 80-898 | 80-935 | ..... | 100-941 | ..... | 83-1009 | |

| HRC | 20.4-67.1 | 19.8-68.2 | ..... | 20.7-68.2 | ..... | 22.2-70.2 | ||

| stainless steel | HV | 85-802 | ..... | ..... | ..... | ..... | ..... | |

| HB | 85-655 | ..... | ..... | ..... | ..... | ..... | ||

| HRB | 46.5-101.7 | ..... | ..... | ..... | ..... | ..... | ||

| HRC | 19.6-62.4 | ..... | ..... | ..... | ..... | ..... | ||

| grey cast iron | HB | 93-334 | ..... | ..... | ..... | 92-328 | ..... | |

| ductile iron | HB | 131-387 | ..... | ..... | ..... | 127-364 | ..... | |

| aluminium alloys | HB | 20-159 | ..... | ..... | ..... | ..... | ..... | |

| brass | HB | 40-173 | ..... | ..... | ..... | ..... | ..... | |

| HRB | 13.5-95.3 | ..... | ..... | ..... | ..... | ..... | ||

| bronze | HB | 60-290 | ..... | ..... | ..... | ..... | ..... | |

| copper | HB | 45-315 | ..... | ..... | ..... | ..... | ..... | |

Types of UCI probes

| Load of probe | advantages | suitable for use |

|---|---|---|

| 5kgf (50N) | Universal type, suitable for most of standard applications. 50N probe is activated by pressure of a hand downwards. Possible to take measurements on surfaces with relatively higher roughness. |

Suitable, for example, for measuring of hardness of camshafts, turbines, welds, measuring in grooves, surfaces of gears, turbine blades, pipes with diameter up to 90mm. |

| 1kgf (10N) | The probe is easily used on curved surfaces. It is not needed to make as high pressure on it as on 50N probe. Measuring accuracy depends on quality of a surface, necessary to measure on surfaces with lower roughness. |

Suitable for measuring of thin-walled parts, parts of bearings, surfaces of teeth on turbine blades, pipes with diameter over 90mm. |